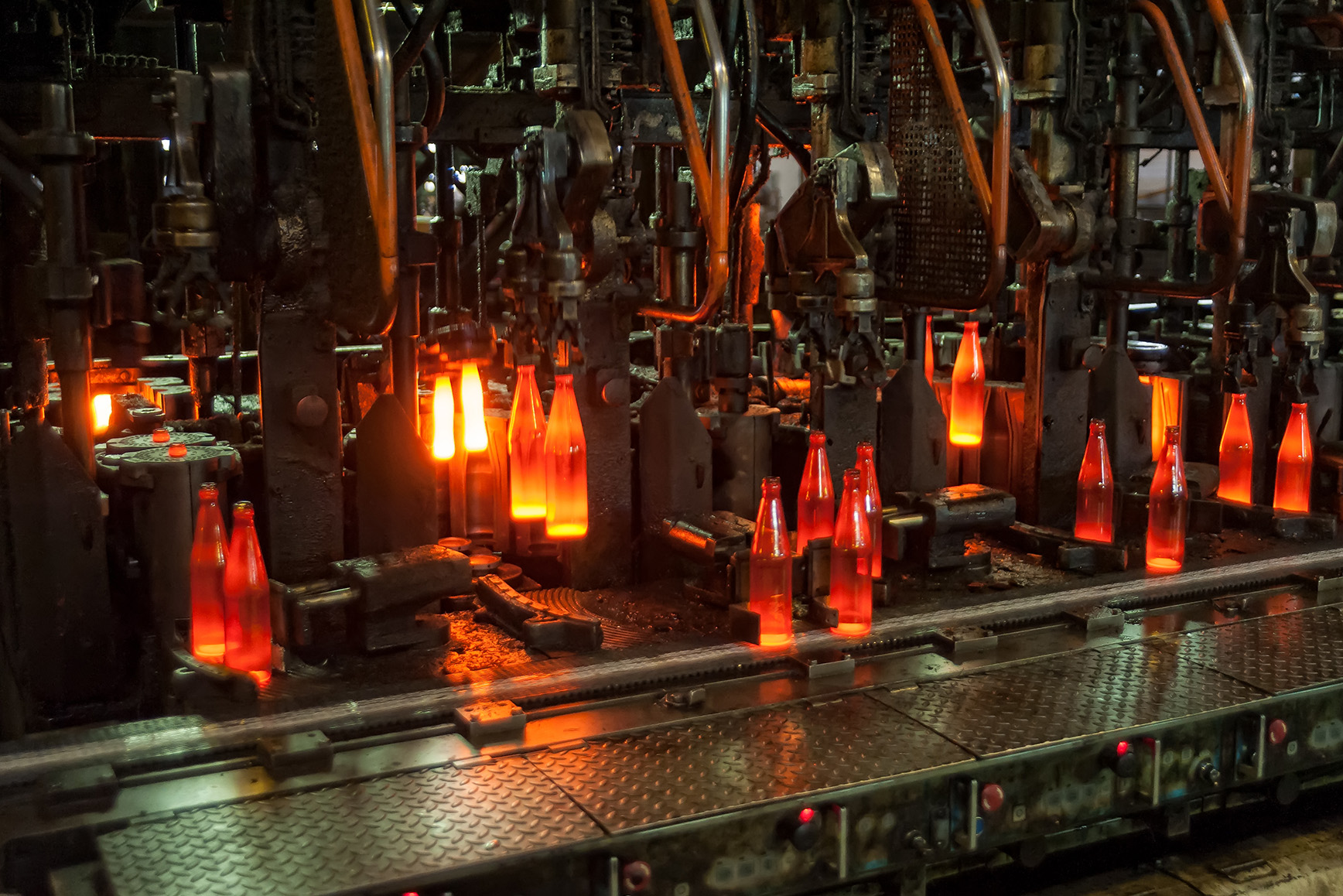

Glass

King Industries has extensive nationwide experience in the Glass Industry since 1987. Specializing in design, fabrication, and installation of process piping and cooling wind systems for furnaces and all associated equipment and systems, we have a reputation of getting the job done on time and within budget.

Other services we provide include fabrication and installation of ductwork, miscellaneous steel on furnaces, refiners, forehearths, and machines. We have experience with hot-work repairs, machine removal and replacement, batch house equipment, material handling systems, and a wide range of other services. With our industry partners and subcontractors, we are able to offer complete furnace rebuilds, modifications, mechanical systems design, engineering and construction services.

Systems and components include:

Melter Re-circulating Cooling Water

Furnace Pressure

Conventional Melter Gas/Air Combustion

Melter Oxy/Gas and Conventional Burners

Melter Block/Crown/Port Cooling Air

Electrode Thermocouple Cooling Air

Melter & Regenerator Quench Air

Refiner & Forehearth Combustion

Refiner & Forehearth Gas Safety Skids

Refiner & Forehearth Thermocouple Cooling

Refiner & Forehearth Fan Skids

Refiner/Regenerator Support & Binding Steel

Machine Drip Pan & Gob Chutes

Machine & Conveyor Cooling Air

Compressor, Dryer, & Vacuum Re-circulating

Utility Piping

Drain Design & Implementation

Electrode Re-Circulating Cooling Water

Melter Oxy/Gas Combustion

Oxy/Gas & Conventional Gas/Air Safety Skids

Melter Oxy/Gas Safety Skids

High & Low-Pressure Throat Cooling Air

Peep Hole Cooling Air

Melter Batch Wetting

Refiner & Forehearth Combustion Skids

Refiner & Forehearth Primary Cooling Air

Feeder Mechanism Cooling

Melter/Forehearth Support & Binding Steel

Equipment Platforms, Catwalks, Stairs, Railings

Machine Hi/Low Pressure Air & Vacuum

Compressor, Dryer & Vacuum Equipment

High/Low Pressure Air & Vacuum

Cullet Re-Circulating Cooling Water

Heat-Up Support

King Industries Inc. maintains a collection of individuals who are dedicated to Glass Industry Projects.

Plan & Spec Team

Specifically trained and experienced in the fabrication of components for glass projects. It offers budget proposals, material, equipment fabrication, procurement, scheduling and installation per clients accepted design criteria.

Design Build Team

Specifically trained in quality installations from a design concept and/or clients design criteria. Services include establishing project scope, design, and scheduling. We assist with budgeting, provide drawings and specifications, and include on and off-site project administration throughout the project.

Construction

Our workforce on installations includes pipefitters, sheet metal workers, ironworkers and masons.

Emergency Services

With our experience in shutdown situations as well as our emergency mobilization plan, down time is kept to a minimum.

Our experience includes projects with Anchor Glass Containers, Saint Gobain Containers, Ardagh, GE Lighting, Cameron Glass, Owens Illinois, Gerresheimer Glass, Arkansas Glass, Phillips Lighting, Lancaster Colony, Rocky Mountain Bottling, and Johns Manville.